ZHZF-300C

Product Description: Our company specializes in the production of 3D car four-wheel positioning. The following products are just one of the software. The company has six softwares for the production, sales and operation of the company's four series of products. This software is available in multiple languages, but the first side is displayed in both Chinese and English. After selecting the language option, the language version is displayed. For details, please refer to the product manual, and the product guidance application. The relevant information will be attached when shipping. Software for export to countries.

Name: Zhuhai Zhanfeng 3D Series Four Wheel Aligner

Model: 3DZHZF-300c

3D-(ZHZF) car four wheel aligner;

Place of Origin: China - Zhuhai

Registered trademark: Zhuhai Zhanfeng (ZHZF)

Operating system: Genuine WIN8-32 bit, multi-model reflective target design, Mandarin and English multi-language or election.

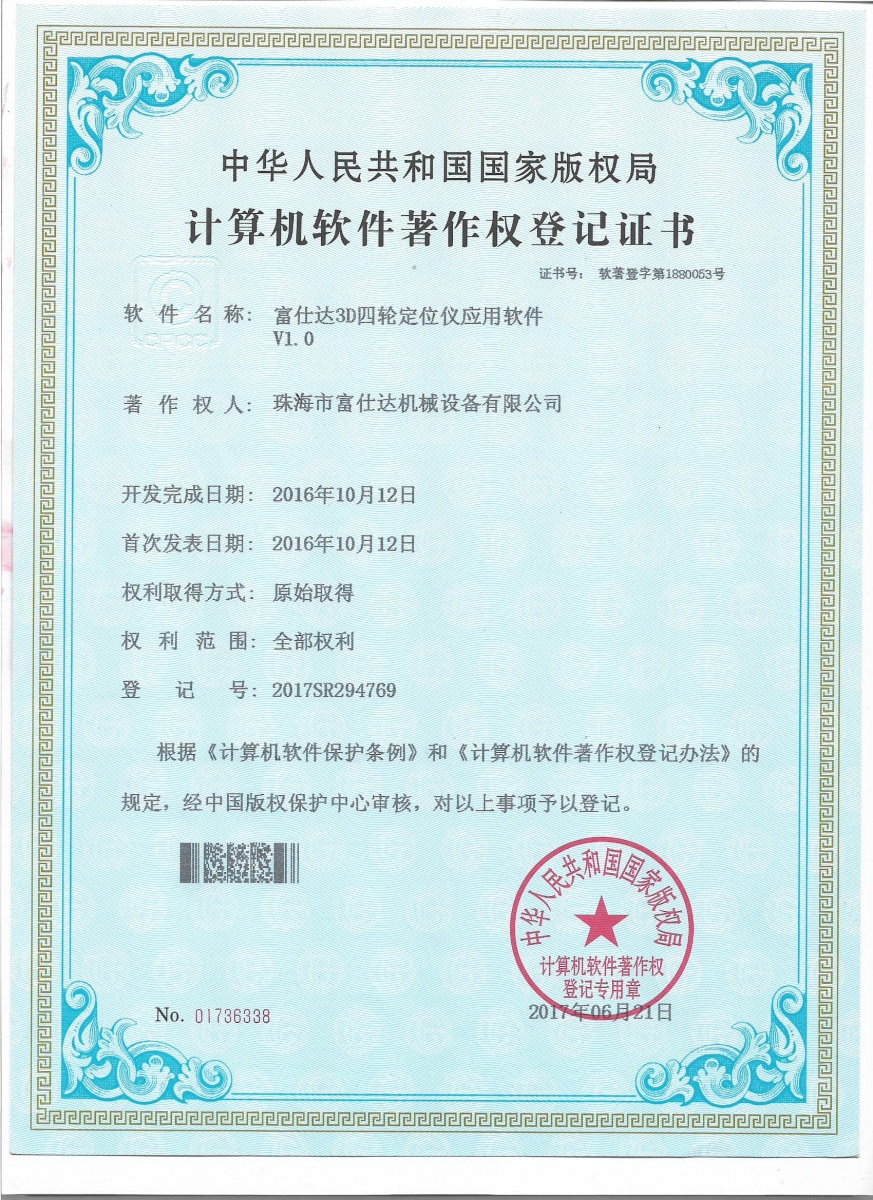

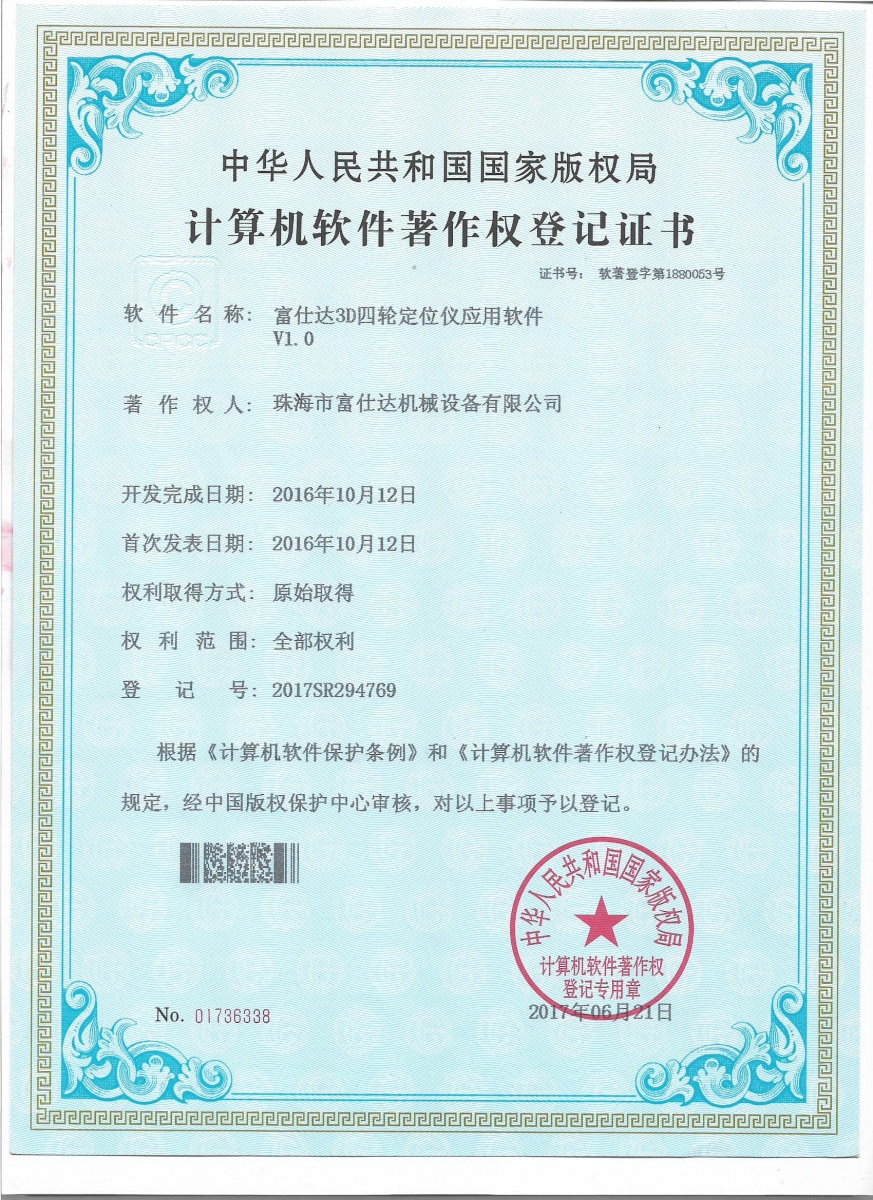

The software operation surface and registered patent certificate are as follows:

The product appearance picture is as follows: (main color has red, blue)

- Product features: the cabinet adopts movable cabinet, convenient installation and low fixed Shidiao column height; the camera uses SONY imported camera 5 million pixel camera system, image processing speed of 30 frames per second, reflecting plate shell using aerospace Aluminum Alloy materials, dynamic visual algorithm technology, the software is easy to quickly read data; 3D dynamic image display operation guidance operation; rolling compensation, short wheelbase, micro distance trolley track difference, accurate detection data, target real-time monitoring, standard four point fixture can check 10-23 inch rims, the equipment maintenance is simple, no need of regular calibration; Aluminum Alloy. Easy to check the angle of the direction of the base parameters and the front wheel angle and other parameters; super database, free of charge to update the database file once a year; the product through the ISO quality system and the EU CE safety certificationThe main technical parameters are as follows:

| Location parameter | Accuracy (center value) | Accuracy range | Maximum measuring range |

| Display accuracy and measurement accuracy | ±0.01°/0.01mm | Measurement repeatability±0.01°or0.01mm | |

| Toe | ±0.015° | ±0.01° | ±30° |

| Dip angle | ±0.025° | ±0.01° | ±30° |

| Kingpin inclination | ±0.025° | ±0.01° | ±15° |

| Kingpin inclination | ±0.025° | ±0.01° | ±20° |

| thrust angle | ±0.015° | ±0.01° | ±6° |

| Maximum turning angle | ±0.015° | ±0.01° | ±30° |

| Recession angle | ±0.015° | ±0.01° | ±6° |

| Tread | ±0.25cm | ±0.01° | 3000mm |

| Wheelbase | ±0.25cm | ±0.01° | 8000mm |

| diagonal | ±2mm | ±0.3cm | 12000mm |

| Rolling radius | ±2mm | ±0.3cm | 700mm |

0.1. The camera has fast response, low temperature performance and good, can work at subzero temperature of about 30 degrees, the cart time is only 3S, the camera speed of 30 photos per second speed

0.2. Reflective board over the horizon, can be in the range of about 12 meters to find the target, you can do longer vehicle detection;

0.3. Measurement accuracy in the industry first-class;

0.4. Software supports a variety of reflective patterns;

0.5. The product has passed ISO quality system certification and export CE certification;

0.6. Guan Jian for aerospace aluminum alloy 7075-T6 super hard aluminum to do

0.7. Computer attached to the 3D operation of the screen, simple and convenient operation. With its own installation and operation guide function

0.8. The software is easy to operate, easy to use, intuitive 3D display

0.9. National UNPROFOR, remote service system

10. All over the country are equipped with after-sales service outlets, remote technical support

11. Regular return visit system of products, continuous innovation, once a year free update data packets

12. The product is specially designed for the drainage design. It is convenient to check the data

13) free training staff

14. Dynamic calculation of the body parameters, not subject to the impact of the lifting machine

15. Automatic calculation of body parameters and rolling compensation body parameters

16. Software intuitive response to the four round of the condition and need to solve the problem of repair